The thin boning knife a professional knife, perfect for mincing and slicing, powerful yet not too heavy.

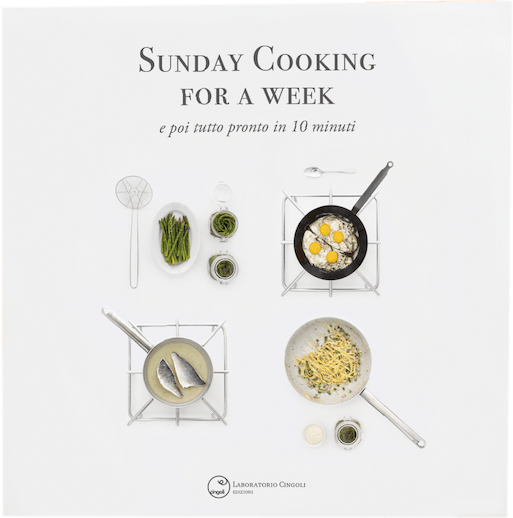

Libro Sunday Cooking for a Week: 31,50 € (invece che 35€)

READ MORE

Libro Sunday Cooking for a Week: 31,50 € (invece che 35€)

READ MORE

The thin boning knife a professional knife, perfect for mincing and slicing, powerful yet not too heavy.

60,00 €

free shipping within Europe

– it is a working knife. Out of all the knives in the CarbonSteel series, this one is the most indicated for daily professional uses

– suitable for both tip and blade use

– perfect for mincing large quantities of vegetables for soffritto, as well as for for slicing fish and meat. Its size also allows it to be used for cutting into hard skins and surfaces

– the perfect balance between weight, size and versatility

– its ergonomic handle makes it easy to grip and quick to clean

– full length: 33,5cm

– dimensions of the blade: length 195mm, height 46mm, width 3mm

– polypropylene handle

Carbon steel, commonly called iron, is glassier with respect to inox steel. Inox is more flexible, almost rubbery, which makes it hard to sharpen. In contrast, iron is very easy to sharpen, and any sharpening tool will yield a razor-sharp blade.

Follow this link to see videos explaining 4 different knife sharpening techniques.

The carbon steel used in our kitchen knives naturally undergoes an oxidization process over time. We recommend carefully drying the knives before putting them away. The surface will eventually turn a bronze colour, typical of these materials.

When I was younger, I used to have one of those Opinel knives with the wooden handle and the dark blade. Unknowingly, I was already using carbon steel knives. It didn’t take me long to notice how easy it was to sharpen the blade by using a grinding stone. At the time, I used a stone typically used for sharpening sickles, very similar to the ceramic stone I use now.

Like many other chef, as I got older, I developed an interest for Japanese knives, which are typically made of carbon steel and have razor-sharp, easy to sharpen blades. The only caveat is that they need to be accurately dried after use, and, sometimes, greased.

The main fault of Japanese knives, for a chef like me, was the shape of the blades. While it is not impossible to use them in our local cuisine, our blades are a better fit for our typical uses. Indeed, western blades evolved over time to adapt to the functions we needed them to perform.

I therefore started looking for iron steel knives with western-shaped blades, but in many years, I only found them in old flee markets. The only alternative were blacksmiths and craftsmen who would forge the blades individually, often at very high costs and with unpractical shapes.

Carbon steel knives had been mass-produced until the late 1950s, when they were substituted for stainless steel, which is not as performing in terms of sharpness, but is easier to maintain. In fact, as the name suggests, stainless steel doesn’t oxidize.

I decided to try and design a modern blade, with western shapes and up-to-standard handles, using this old material: kitchen knives in carbon steel.

My friend and architect Daniele Borin’s help was fundamental to the designing stage of these knives. Together, we decided to turn to a small firm in Premana, renowned for its excellent knife production: Fratelli Rizzi.